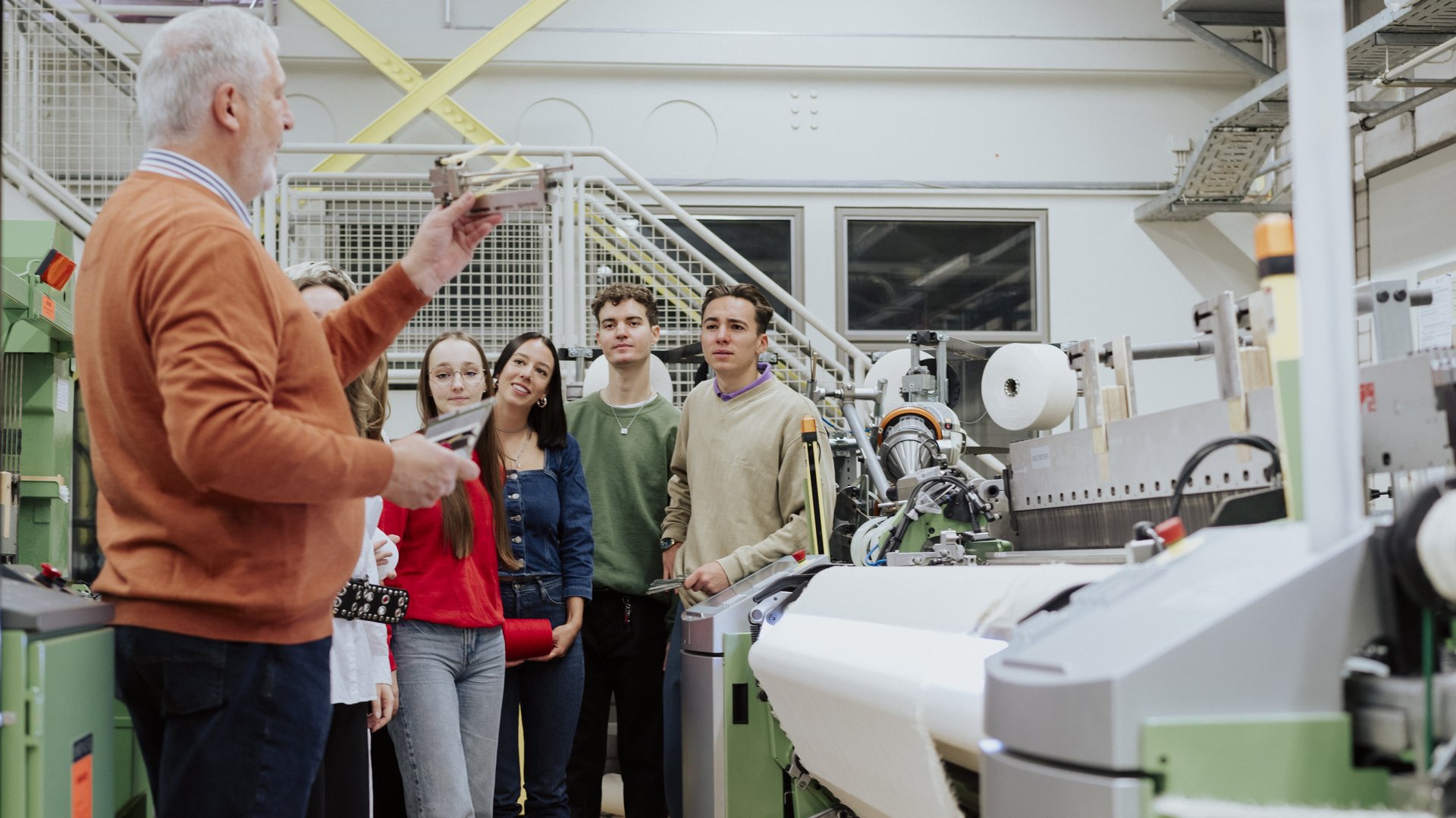

In the weaving technology laboratory, students can experience the processes involved in manufacturing fabrics on industrial production machines. Hands-on technology ideally supports the theoretical lectures on process engineering in weaving. Processes for warp production are shown as well as weaving processes with various weft insertion systems and shedding devices.

Numerous broadlooms and ribbon looms are available to demonstrate the different technologies for various fields of application. Demonstration models are available for a better understanding of special motion sequences. The technological understanding of the interrelationships between the process parameters is deepened with the use of electronic measuring devices.

Technical equipment

- CAD department for computer-aided weave and pattern programming for dobby and jacquard fabrics

- Production on industrial projectile, rapier and air-jet weaving machines with up to 900 weft insertions per minute

- Electronic measuring devices for yarn tension measurement for the analysis and optimisation of machine settings

- Various functional models for visualising and understanding the movement of important machine components

- Hand looms for weave and colour sampling to test numerous design ideas

The laboratory is used depending on the study programme in the form of group practicals or individual project work as well as for individual project work, research work, Bachelor's and Master's theses.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/6/csm_Scholze_Ulrich_TEXOVERSUM_2024_1b107f0d2d.jpg)